Fiberglass Honeycomb Core Panel Building Material

Basic Info.

| Model NO. | AHP |

| Level | A |

| Application | Interior Decoration |

| Use | Stone Backing |

| Transport Package | Wooden Pallet |

| Specification | 1220x2440mm |

| Trademark | Kingmets |

| Origin | Guangdong, China |

| HS Code | 39219090 |

| Production Capacity | 500m2/Day |

Product Description

FRP Fiberglass Honeycomb Panel

FRP Fiberglass Honeycomb Panel is consisted of two FRP sheets as face sheets being laminated to a honeycomb core. We use two components PU glue to bond the 3 layers of material which provides a super bonding strength.

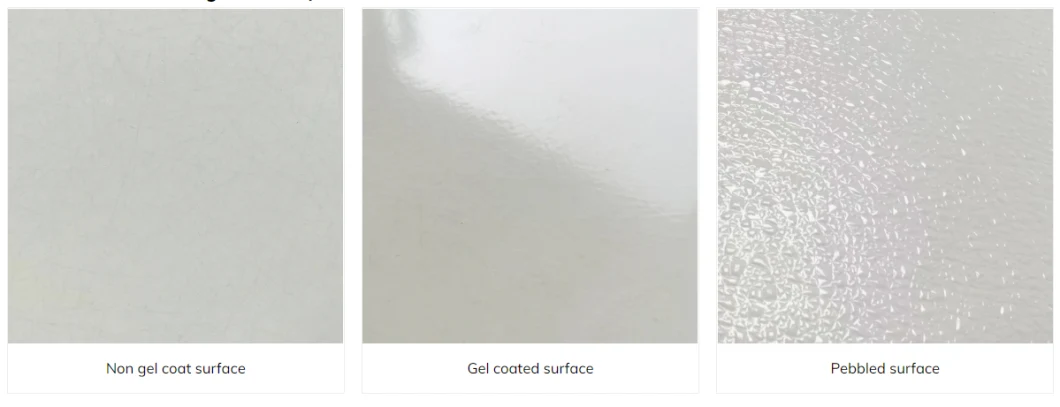

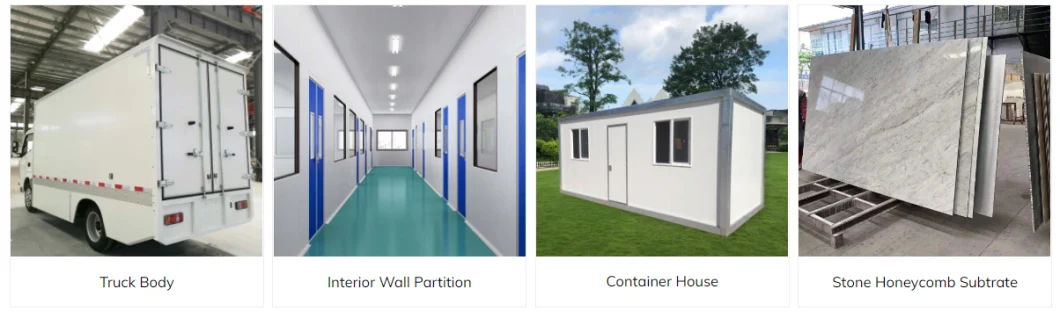

FRP is fiberglass reinforced plastic which is a high strength, durable and chemical resistant material. And the FRP surface can be gel coated surface or rough surface without gel coat. While the honeycomb core can be aluminium honeycomb core or PP honeycomb core. And FRP honeycomb panel is used for vast applications, mainly for dry van truck body, building partition walls and substrate panel to glue stone or porcelain tiles etc.

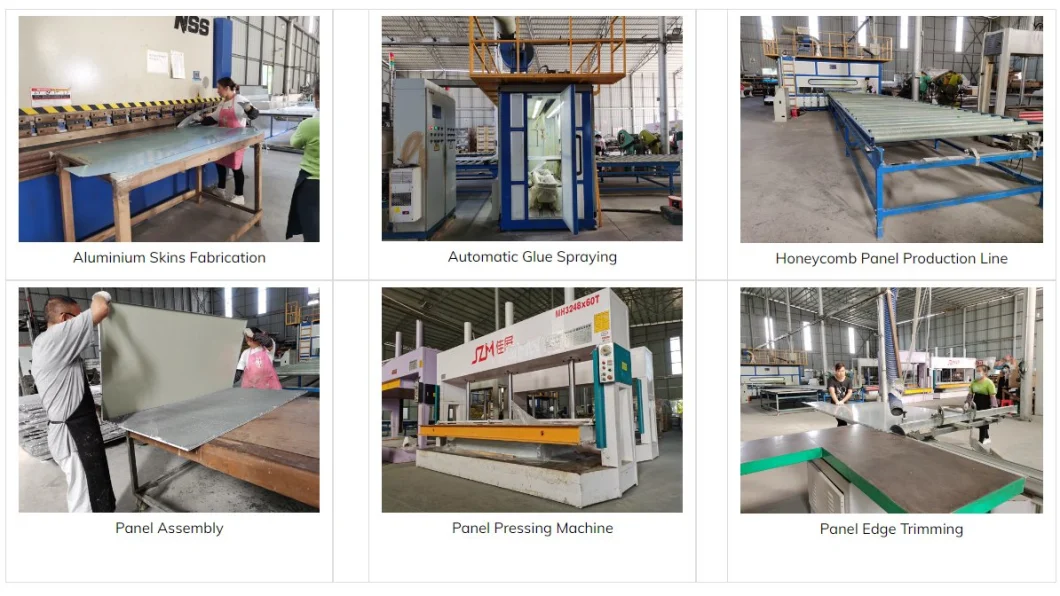

Our FRP honeycomb panel is manufactured through automatic glue spraying process & high pressure pressing process, life span is long.

Specifications of FRP Fiberglass Honeycomb Panel

Panel thickness | 10mm, 18mm, 20mm, 25mm or customized thickness |

Panel width | 1000mm, 1220mm, 1500mm or customized widths |

Panel length | 2440mm, 3200mm, 4000mm, 5800mm or customized lengths |

FRP skin thickness | 1mm, 1.2mm, 1.5mm, 2mm, 3mm or customized thickness |

Honeycomb core | Various aluminium honeycomb core, or PP (polypropylene) honeycomb core |

| Panel edge | Standard open edges |

FRP patterns | Smooth surfaces, pebbled surfaces |

Color options | Matt gloss or high glossy colors: white, grey, black, red, blue etc |

Gel coat | Gel coated or non gel coated optional |

| Fiberglass types | chopped fiber, woven roving types |

Key Benefits of FRP Fiberglass Honeycomb Panel

| High strength | Light weight | |

The hexagonal honeycomb structure provides excellent panel strength to support the fiberglass skin sheets. And the three layer structure provides super tensile strength between the skins to the core layer, making the panel stays at good strength over time. | Owing to the hollow light weight structure of honeycomb core, the density of honeycomb panel is small and the weight for each square meter is low. The density for FRP per mm thick is only 1.4kg/m2, and aluminum honeycomb core is only around 35kgs/m3 (PP honeycomb core at 80kgs/m3). | |

| Highly durable | Stable quality | |

FRP face skins are made with mixture of fiberglass & high quality resin. The surfaces are strongly scratch resistant, high impact resistant, UV resistant & chemical resistant. The panels could last for decades under normal using conditions. | Both the FRP (fiberglass reinforced plastic) and PP honeycomb core are thermoplastic, such panel components can perform mechanically & physically stable under a wide range of temperatures from -40ºC to +80ºC. | |

| Easy installation | Easy maintenance | |

Installation of honeycomb panels can be connected by using proper designs of aluminium extrusions along with screws or rivets. | The FRP face skin sheets are not easy to get dirty. And FRP is water proof material, it's easy to clean with regular detergents & high-pressure washers. |

Patterns of FRP Fiberglass Honeycomb Panel

Applications of FRP Fiberglass Honeycomb Panel

Workshop at a Glance

Technical Data of FRP Fiberglass Honeycomb Panel

| Basic Information | |||

| Item | Value | Tolerance | |

| Panel thickness | 10mm | +/-0.2mm | |

| FRP skin thickess | 2mm (Top) + 2mm (Bottom) | +/-0.03mm | |

| Fiberglass type | Chopped fiber / Woven Roving | ||

| Honeycomb core | Aluminium Honeycomb A6*0.05 | ||

| Panel width | 1220mm or customized | +/-2mm | |

| Panel length | 2440mm or customized | +/-4mm | |

| Diagonal | N/A | ≤5mm | |

| Flatness | N/A | <2mm/m | |

| Panel weight | 6.61kgs/sq.m | +/-5% | |

| Physical & Mechanical Properties (based on chopped fiber type) | |||

| Property | Test Result | ||

| FRP skin sheet density | 1.4g/cm3 | ||

| Glass fiber content (in FRP skin sheet) | 27% | ||

| FRP hardness | 40/42 Barcol | ||

| Tensile Sterngth, Rm (FRP skin sheet) | 85Mpa | ||

| Shear strength (FRP skin sheet) | 115Mpa | ||

| Honeycomb Core Shear Ultimate Strength | 0.77Mpa | ||

| Peel Torque | 7.23mm·kgf/mm | ||